Snobar Clamp and Roof Clamp Salt Test

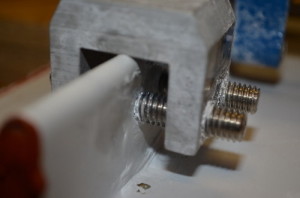

Over the past few years there has been a lot of debate between roof clamp manufacturers about which type of set screw is best for metal roof attachment. We have conducted a series of tests over the past year showing the differences between the two types of set screws, cupped tip and round tip. The full video and results can be found at www.TruthAboutSetScrews.com.

We decided to go one step further by initiating ASTM B117 Accelerated Salt Spray Corrosion testing on all of our bar systems, clamps, and our competitor’s components as well. After 1,006 hours of testing on the first panel, it was removed and disassembled. Here are some findings from the test:

This is contrary to the false claims competitors who insists that round tip set screws are the only type of screw that doesn’t cause attachment point corrosion. Lab testing proved that cupped tip set screws do not cause premature corrosion at the attachment points.

We first discovered this flaw when doing the video clamp testing last year, once we installed and reinstalled the clamps a couple of times, they started to get harder and harder to turn the set screws as the fine threads became clogged with aluminum shavings from the soft clamp threads. Then after the salt spray testing, we experienced the same problem when the tip on our torque wrench sheared from trying to remove the set screws. The problem with this defect is that these clamps have a very limited ability to be removed, adjust, re-torqued, or reinstalled once the set screws lock up. If they were used to install a bar system with round point set screws that eventually slid down the seams, it would be nearly impossible to reset the clamps back to the correct seam location once the set screws were locked up. The set screws would have to be drilled out or the clamp cut off the seam.

In summary, cupped tip set screws for bar mounted snow guards are far more efficient at staying in place on the seam by only requiring 90in/lbs of torque. Round tip set screws for bar mounted snow guards are far less efficient at staying place and therefore must be highly torque from 130in/lbs to 180in/lbs depending on the gauge of the panel. This causes seam distortion and can affect the waterproofing seal in the seam which can lead to other issues down the road. The salt spray test also proves that neither type of screw causes premature corrosion at the attachment point and neither screw should void any paint or panel warranty since they both perform in the same manner. See more test information at www.TruthAboutSetScrews.com.

"Now In Stock"

SnoBar Colorbar WindBar

* Same Day Pickup

* Online Ordering

* Super Fast Shipping

* Colors in 4 Weeks